A user’s experiences

Advances in boiler and water-heating technology over just 20 years impressed Tony Cella, site manager of Queensbury Academy in Dunstable when he embarked on an ambitious replacement programme in the west block — in the winter.

December 2012 was never going to be a good time to start a major replacement project for fan convectors and boilers in an occupied upper school. But December it was to be, and contractor CME Heating moved in to start the work.

The new Biddle fan convectors were replaced room-by-room, with the main block convectors planned for February half term.

The boiler upgrades were to be A O Smith Upsilon boilers and BFC Cyclone water heaters.

The first boiler house, serving a gymnasium area, had at Upsilon 70 fitted and a BFC water heater to replace the aging, but still working, A O Smith unit. There were a few chilly days towards the end of December changeover in the gym area, but the PE staff just made the kids work harder to keep warm.

The system for the main block system comprised of six boilers dating from around 1992 split into three systems with two boilers per zone and a newer direct-fired water heater. These were to be replaced with six new Upsilon 140 kW boilers on a common header with modulating valves to each zone. A low-loss Spirotech 100 air/dirt separator was also fitted to cope with any debris in the old system.

To install the new boilers we would need to remove three of the old boilers and leave the others running 24/7 to try to maintain the building temperature. Each boiler barely managed to achieve a flow temperature of 60°C on its own in what was to be a very chilly winter period. Another BFC 60 water heater completed the system in the main block.

As site manager of the school and an ex plumber I took a keen interest in the new plant being installed.

As the first boiler casing came off I thought this is not a boiler but more like a stainless-steel car engine, with its tubed manifolds and angular shape. It seemed a shame to put a plain grey steel casing around such a thing of beauty.

These were the first Upsilon boilers that CME had fitted so it proved to be a learning curve for them too, particularly during first start up when the boilers decided to do their 13-minute power up (blocking) program. In a further break from tradition the burners gradually ‘ramp up’ on ignition, which I am told reduces thermal shock on the components rather than starting on full load before modulating down.

CME Heating was impressed by the frame-mounted manifold system and the accurate fit of the pre-formed components. Inbuilt diagnostics in the boiler control panel let you see exactly the temperature and percentage burner rate for any particular unit — as well as fault diagnosis, service interval and hours run.

I think one of the most impressive features of both the BFC water heaters and Upsilon boilers is the quantity of condensate they produce, even when running above 55°C. The top-firing burners of the heaters and the ultra-low level of modulating burners contribute to achieve maximum levels of heat reclaim from the flue gases, and when running at lower temperatures a steady stream of condensate is flowing most of the time.

Performance and economy is where I feel the academy will see the most benefit. Morning start up is down to about 20 minutes, even on the furthest circuit in the block. Traditionally it took over an hour to achieve working temperatures, but the new boilers soon modulate down to a lower rate for the rest of the working day.

Combined with the Kieback & Peter BMS controls, initial indications are of greatly reduced gas consumption. The academy has only had the web-based automatic meter-reading service running since July 2012 so year-on analysis was not possible. However, a comparison with a similar-size block on the site which traditionally had very similar consumption on any particular day has shown a weekly (in April) saving in excess of 25% when compared to a week in November (old system) with a similar degree-day rating. I am looking forward to presenting my annual energy statement to the academy governors and many years service from our new boilers.

|

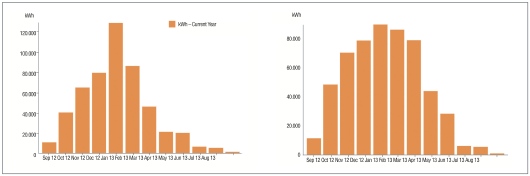

| Comparing the pattern of gas consumption for the west (left) and east blocks reveals a marked improvement in the west block in March. The high consumption for the west block in January was when only half the boilers were operating 24/7. |

The charts of gas consumption for two of our main blocks indicate how efficient the new equipment is. The new west-block boilers came on line at the end of February, and consumption since then has dropped considerably compared to the east block.

Note the period in January of 24/7 operation of old boiler plant and the substantial reductions in March and April 2013, both cold months

The east block conventional boilers were in use for one extra week in April compared with west block. With this week removed east-block consumption would be in the region of 31 MWh compared with 21 MWh for the west block.

As an added bonus, the frame-mounted Upsilon boilers take up less than half the space of the old boilers, so I have gained additional workshop space and in time maybe a comfy chair tucked in the corner — which the super quiet boilers will help ensure I am not disturbed too much.