Daikin advances the efficiency of VRV

Daikin made the air-conditioning industry sit up and take notice when it brought VRV air conditioning to Europe in 1987. The latest development is set to do the same, as Ken Sharpe found out.

Every now and again a step change in the performance of building-services plant comes along. Boilers are hugely more efficient than they were, say, 20 years ago. Variable-speed drives have seen the overall energy consumption of pumps, fans and refrigeration compressors fall dramatically — while, at the same time providing better environmental control. As for lighting, lamp efficiency just gets better and better, and controls to detect the presence of people and the availability of daylight minimise the amount of artificial light that is provided.

The pace of development is way behind Moore's Law, which says computer processors double in complexity every two years. Take-up is much slower, too, but every now and again comes a development to sit up and take notice of. Perhaps, fortuitously, building-services plant has a much longer life than IT equipment.

Daikin reckons it has achieved just that with its latest development of VRV heat-recovery air conditioning. A fundamental change in the control and operation of the VRV IV heat-recovery system achieves 28% higher efficiency than the previous generation of VRV (VRV III).

‘Not since 1990 when we introduced inverter-controlled compressors on VRV systems has there been such an advance in efficiency,’ says Richard Green, Daikin Airconditioning UK’s VRV product specialist.

In previous VRV systems, cooling capacity has been matched to demand by varying the volume of refrigerant delivered. The breakthrough in the latest system is also to vary the flow temperature of the circulating refrigerant.

Varying flow temperature is a familiar concept in heating and chilled-water systems, but apparently not in VRV (or VRF as it is generically known) systems.

|

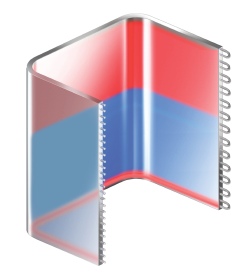

| The 3-pipe heat-recovery system and branch selection boxes with up to 16 pairs of connections deliver major installation benefits. |

Controlling the evaporation and condensing temperatures of the refrigerant in response to load and ambient temperature is the main reason for the large increase in efficiency if VRV IV. Raising the evaporation temperature also reduces the risk of cold draughts from the indoor units. Richard Green says that the concept could be described as ‘weather compensation for cooling’.

Despite various teasers for VRV IV having been around for some time, the system will not be available in the UK until the autumn.

In the meantime the results from a field trial at a fashion chain store in Germany involving the replacement of the two outdoor units of a 20 hp VRV III system with s single 18 hp VRV IV unit showed a 32% improvement in efficiency over a year (see diagram). Indoor units were left in place, and daily energy consumption was compared with the daily difference between average shop temperature and ambient temperature.

The VRV IV system consumes much less energy than the VRV III system — in some cases, up to 60% less. When heating, savings averages 20%.

When cooling, the refrigerant temperature varies from 6 to 16°C, so the units do not blow out cold air. When heating under partial load, the refrigerant temperature varies from 38 to 49°C.

A seasonal EER of up to 7.53 is claimed for VRV IV in cooling mode, which meets the expected future targets of the European EcoDesign Directive for VRV/VRF products due to come into force after 2016.

|

| Note the interchangeable 60/40 split between heating and cooling — and also the permanently hot zone at the bottom to provide continuous heating during defrost. |

A VRV IV system continues to deliver heat during defrosting. Instead of reversing the refrigeration cycling and losing heating capability for a time, a heat-accumulating element at the bottom of the coil stores energy for use during defrosting while indoor units continue to deliver heat.

Another key to the efficiency of VRV IV is the multi-stage heat-recovery coil. It wraps around all four sides of the compressor, rather than just three and is three rows thick rather than two. The effect is to provide 50% more surface areas across which heat can be exchanged, reducing the compressor power required.

The proportion of the coil that is used for heating/cooling is split 60/40, and the ratio is reversible, or the whole of the coil can be used for heating or cooling.

Heat recovery is based on the use of three pipes to the branch-selection (BS) boxes — one pipe each for gas, liquid and discharge to enable heat to be recovered at high temperatures. In a 2-pipe system, gas and liquid travel through the system components as a mixture, so heat cannot be recovered at the same high temperatures.

BS boxes for VRV IV now have up to 16 pairs of pipes for connecting indoor units and will fit into a 300 mm ceiling void. There are boxes with 1, 4, 5, 6, 8, 10, 12, and 16 connections. Each port can be connected to a 14 fan coil and provide heating or cooling. In theory, only one port need be connected, leaving the rest for future needs. The availability of BS boxes with so many connections instead of single BS boxes has significant installation benefits. Richard Green suggests that up to 32% less copper piping might be needed, with a hot works reduced by over 40%.

Finally, Richard Green points out that VRV IV is only offered for heat recovery, which is well suited to the UK market, where 70% of VRV/F systems are heat recovery.