The then and now of boilers

From the atmospheric boilers of the 1980s and 1990s to the latest condensing units and renewable offerings available today, Peter Gammon of Elco UK takes a look at how energy efficiency has shaped the building-services industry.

At the turn of the millennium, the commercial boiler market was a very different landscape to the one seen today. Over the last decade and a half, manufacturers have completely reinvented the sector — to such an extent that the latest models have the potential to significantly reduce running costs and are hitting the ceiling of achievable efficiencies.

So, how has this been achieved, and how has the commercial boiler market changed? Well, in the late 1990s, atmospheric and pressure-jet boilers still dominated the spec. sheets. Solid and reliable, these appliances are still around in some form today, but the commercial market needed to adapt to customer requirements, including higher outputs from shrinking plant rooms. This formed a dramatic change of approach, and wall-mounted condensing boilers have become the appliance of choice for a huge section of the commercial market.

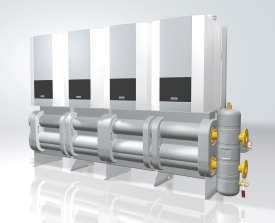

Today, this category of boiler dominates the new and retrofit markets, and a quick glance at any manufacturer’s boiler range is testament to its ascendancy. Quite simply, wall-mounted units — in many circumstances — make sense, especially when in cascade. Not only do they provide an inherent standby in case of breakdown, but a cascade system comprising several boilers also provides the advantage of deeper turndown ratios compared to one or, even, two larger boilers. This allows the heat generation to be matched closely to the load, ensuring the system is more seasonally efficient and further promotes fuel savings and emission reductions.

|

| Modern boilers, such as Elco’s Thision, are pushing the limits of efficiency. |

It’s also noteworthy to evaluate the improvements in boiler efficiencies over the years. Yes, the industry is now banging the ceiling of efficiencies, but 10 to 15 years ago, there were still atmospheric boilers with gross efficiencies of just 79%. When compared to a modern gas-fired condensing boiler, such as the Thision L from Elco, there has been an improvement in energy efficiency of around 9% (calculated on the same basis); that’s quite a developmental leap.

There are also a number of legislative reasons for the advent of these highly efficient products. Undoubtedly, one of the main drivers behind energy efficiency since the early 1990s has been the revamped and strengthened Building Regulations — particularly Part L. This focused the industry on the conservation of fuel and power, which consequently led to increased energy efficiency of boilers themselves. Combined with an eye on the wider building fabric, the potential carbon savings that could be made were significant.

So, where does the industry go from here? As discussed, the level of efficiencies available from commercial boilers is unlikely to make the dramatic leaps of the last couple of decades. Some industry analysts might suggest the answer is renewables. In many applications, the use of renewables with modern heating systems offers some tangible benefits. However, there is still some reticence to the introduction of these technologies, with the payback period taking too long for the relatively high capital investment. Certainly, this has been reflected in the number of non-domestic RHI applications over the last year, which appears to be plateauing. Further still, the latest sales figures from the Heating & Hotwater Industry Council show a significant drop of 29% over the last year alone.

Yet, regardless of this current reduced uptake of renewable technologies, it is likely that more and more specifiers and consultants will choose them as a way to increase the overall energy efficiency of a building. By combining what’s great about existing fossil-fuel technology, including reliability and tried-and-tested products, with the best of renewable heating systems, energy efficiency can be improved — with dramatic reductions in emissions.

|

| Wall-mounted boilers make sense for many applications, especially in cascade. |

The other consideration for the commercial boiler market is the Energy Related Products (ErP) Directive, which will affect the industry the greatest in 2015. This regulation outlines efficiency requirements for boilers with rated inputs from 70 to 400 kW, which will effectively eliminate all high efficiency non-condensing boilers up to 400 kW. Furthermore, there will be no differentiation between new and existing buildings, which will require many project specifiers to consider replacing the whole system rather than individual units

However, thanks to the developments in the commercial-heating industry since the millennium, the UK is well set for the future requirements. Wall-hung condensing boilers will no doubt continue to be the principal choice for the majority of new builds and replacement market. Plus, with energy efficiency now at the epicentre of products and industry developments — as well as fully ingrained at all levels of manufacturing, specification and system design — the next 10 years look a positive place for the commercial boiler market.

Peter Gammon is technical manager of Elco UK (formerly MHS Boilers).