Bridging the knowledge gap in water-treatment

One of the main reasons commercial boiler manufacturers are called back to site is poor water treatment, yet Non-Domestic Building Services Compliance Guide recommendations on this subject are almost non-existent. Ian Barnes of Sentinel Commercial discusses the critical need for more thorough guidance and explains what building-services engineers can do to ensure the long-term operation and efficiency of commercial boiler plant.

In recent years there have been significant updates to Part L of the Building Regulations for domestic buildings, and (rightly) we’ve seen a greater emphasis placed on the importance of water treatment in ensuring the efficient running of heating systems. The Domestic Building Services Compliance Guide offers explicit and comprehensive guidelines, covering cleaning and flushing, the addition of inhibitor according to the manufacturer’s specification, scale prevention, and the importance of regular maintenance dosing to achieve long-term protection.

|

| Seeking advice from water-treatment specialists can avoid hugely expensive problems. |

However, when it comes to non-domestic buildings, the equivalent document is rather vague on the matter, advising designers that ‘water quality can have a serious impact on system efficiency’ and that they should ‘take appropriate measures to ensure that the system water is of good quality’ (note in sections 2.5 and 8, respectively).

Given the lack of official guidance on the subject, it’s up to commercial water-treatment specialists to bridge the knowledge gap and help engineers avoid the problems that come with poor water treatment, namely reduced operational efficiency, corrosion and the build-up of sludge and scale, which ultimately lead to leaks, breakdowns, system downtime and even complete boiler failure.

These problems can be expensive to fix, and that’s before you even factor in the financial implications of a shortened system life expectancy. When you consider the scale of investment of commercial heating systems (tens to hundreds of thousands of pounds) and their related energy costs in relation to the outlay required to facilitate best-practice water treatment (as little as hundreds of pounds), the case for treatment is clear.

Without a correctly implemented water-treatment programme in place, heating systems are at risk of corrosion, limescale and debris build-up.The emphasis here must be on ‘correctly’, since although many building-services managers are aware of the importance of water treatment and ensure it is undertaken (either directly, by specification, or by subcontracting the work out), there can be confusion over the correct procedures and products. The result is that even though water treatment has been carried out, optimum protection is not in place. To understand how best practice can be achieved, it is helpful to know a little about why heating systems require water treatment.

|

| A simple testing programme will ensure that appropriate water treatment is being carried out. |

Corrosion is the most common problem, and can occur through simple oxidation (leaks and high make-up water usage facilitate excess oxygen ingress) or the interplay between different metals (more reactive/anodic metals will sacrifice themselves to those that are more noble/cathodic), with poor pH stabilisation also contributing to both mechanisms.

The process of corrosion results in metal loss, pin-holing and the creation of sludge that leads to system blockages and reduced heat transfer. In addition it can also erode system components such as pump shaft seals.

Limescale is less of a problem, since it is not so prevalent in closed systems. However, if there are excessive leaks and high water make-up rates, then serious scale build-up and blockages and reduced efficiency can occur.

Corrosion, limescale and pH levels can all be controlled through the use of an appropriate inhibitor, but it is important to match the chosen formula to the system to achieve prime levels of protection. The best water-treatment products are liquid formulas which boast multiple corrosion inhibitors, ensuring that protection is optimised and maximised for all metal types. If there is any aluminium in the system, it’s wise to ensure that the chosen product also offers strong pH buffering/stabilisation. Remember that boiler manufacturers and industry-leading water treatment companies are always happy to offer advice on suitable water-treatment products.

Once the right product has been chosen, pre-cleaning should always be undertaken prior to dosing, whether the system in question is new or already in service. Without this important step, the effect of the inhibitor will always be compromised.

|

| Corrosion is the most common problem of poor water treatment. This corrosion debris has been collected on the boiler filter. |

As with choosing the inhibitor, the chemical cleaner should be selected with system specifics in mind. Industrial mineral acid cleaners can do more harm than good, actually promoting corrosion and causing leaks, so it pays to seek advice from the boiler manufacturer or a leading water treatment specialist, and use only high-quality pH-neutral chemical cleaners.

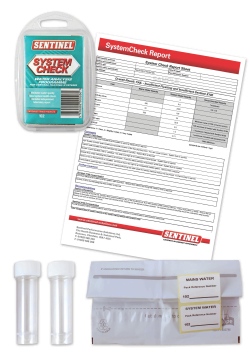

But how can managers ensure that this best practice is always followed? A simple testing programme will provide evidence that the correct procedures, dosing levels and products are always used. Water samples can either be sent away for laboratory analysis, or they can be directly tested using a kit such as SystemCheck. This will ensure that potential problems caused by water-treatment errors can be avoided, and that the water-treatment process meets the warranty conditions of component manufacturers.

The Part L Non-Domestic Building Services Compliance Guide includes little detail on the important subject of water treatment. However, advice and support is readily available from component manufacturers and industry organisations such as ICOM, which offer comprehensive best-practice advice.

Following best practice will not only benefit building owners, occupiers and building-services managers through reliability and smooth running of systems, but the increased efficiency it ensures — along with the avoidance of the costs involved in solving the problems of corrosion and scale build-up — will have a positive financial implication too.

Ian Barnes is head of Sentinel Commercial.