Turning up the heat for energy efficiency

With high-efficiency boilers remaining an important component in UK heating systems, Chris Meir of Remeha Commercial looks at how combining them with improved system design and operation is the key to raising efficiencies in our existing building stock.

A common criticism of the amendments to April’s Part L Building Regulations was the absence of any targets to improve the energy efficiency of our high proportion of existing building stock. These buildings, which account for the majority of UK carbon emissions, have not only been around for a long time but will still be with us in 2050, the year by which we are targeted with cutting our emissions by a steep 80%. The focus in the UK, building-services experts agree, should be to improve the efficiency of our existing estate.

Retrofit technologies have advanced considerably over the last decade, heading up the energy-saving technologies in terms of effectiveness, according to the Carbon Trust.

Where heating is concerned, one of the most advanced retrofit technologies is the high-efficiency gas-fired condensing boiler. Boilers continue to play a key role in heating UK buildings, whether as the sole heating component or as back up for renewable heating equipment.

The clean-burning technology, which is often the only possible retrofit solution for our old building stock, is proven to slash energy by more than half and reduce carbon and NOx emissions by as much as 90%. The familiar, reliable boiler has also benefited from recent advances in design that have further facilitated quick and easy installation for minimum disruption.

|

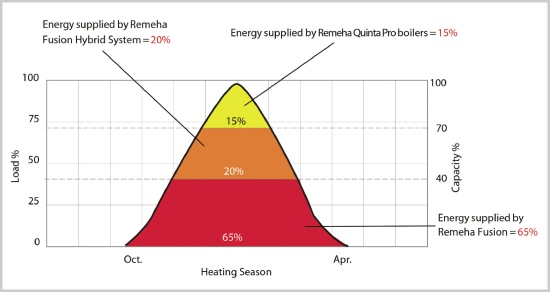

| Despite being size for only 30% of the total heat-load requirement, the Fusion gas absorption heat pump of Remeha’s Fusion Hybrid system accounts for about 55% of the overall seasonal efficiency. The other components are Quinta Pro boilers and fully integrated controls. |

The new regulations set out by the ErP Directive that will come into force in 2015 are intended to encourage the replacement of less-efficient boilers and water heaters with higher-efficiency, new-generation heating technology and improve the efficiency of bivalent heating systems that incorporate renewable energy technology. However, given that manufacturers already offer condensing boilers that meet the new ErP Directive targets, with impressive headline efficiencies of 98%, arguably our real challenge is how to use this state-of-the-art equipment as intelligently as possible to ensure that they achieve their maximum efficiency and effectiveness.

To do this we must concentrate on improving the performance of the system as a whole rather than focusing on the efficiencies of individual components. For optimum energy efficiency in our buildings, the first step is to work out how to achieve the maximum efficiency from the heating system; the second is to use the energy input as effectively as possible.

The reality is that in real life conditions, most boilers — even high-efficiency condensing boilers — waste energy, failing to achieve the high efficiencies quoted and dropping to the standard 80%. This is because the typical existing LTHW system will generally have been sized on high flow and return temperatures, which prevents the boiler from fully condensing and operating at its maximum performance.

A one-step solution to achieving maximum efficiency levels on refurbishment projects is a ‘super-condensing’ heating system that uses passive flue-gas heat-recovery technology. As it takes more energy to heat the old system, it makes absolute sense to recover what would otherwise be wasted energy. This is precisely what a ‘super-condensing’ heat-recovery system does, using the recovered energy for the benefit of pre-heating domestic hot water or space heating and thereby delivering the highest possible efficiency of 107% NCV at all times, irrespective of primary-circuit temperatures.

|

| Since installing three Quinta Eco Plus 65 PFHGR systems at Hatch Mill nursing home in Farnham, Surrey, this 48-bed care home has seen energy consumption plummet with usage on a par with that of the neighbouring 28-bed care home, Wey Valley, despite being almost double in size. |

An alternative solution would be to consider including an allocation for complementary LZC technologies in the boiler plant replacement budget. Combining a renewable technology such as environmentally-friendly gas absorption heat pumps with gas condensing boilers in a hybrid system could achieve a high seasonal efficiency of 120 to 130% NCV. Here again the system design is paramount to achieving these higher efficiencies. Controls are key not only to uniting the components but to integrating them within the heating system for optimum energy and carbon savings. At Remeha, we have responded to this challenge with a bespoke trivalent heating system that combines gas absorption heat pumps and high-efficiency condensing technology with a fully-integrated, scalable building-control system that is specially tailored to meet the individual needs of a building. As the control system can be easily integrated into existing building management systems, a system such as the Fusion Hybrid is perfectly suited for retrofit purposes as well as new build (see diagram).

Once maximum efficiency is achieved, the next step is to add the appropriate controls to use the energy as efficiently as possible. Adding weather compensation or sequential control, say, will allow the boiler to operate at its highest efficiency level, while zoned temperature and time control enable energy-saving operation. With the Fusion Hybrid system, for example, energy use can be operated and monitored remotely via the a touchscreen control panel.

With manufacturers already offering ErP-compliant heating equipment, the technology already exists to improve the energy efficiency of our notoriously inefficient buildings to a certain level.

However, while efficiencies can be raised still higher, we at Remeha Commercial believe the challenge is far from over. With our high-efficiency condensing boilers, all with BIM models to facilitate smarter system design, ‘super-condensing’ technology, bespoke trivalent hybrid heating and hot water systems, and advanced controls, we look forward to supporting the building-services industry in the move towards greater energy efficiency.

After all, while the importance of energy efficiency may be overlooked by current legislation, it is surely the most successful energy-saving measure of all: the more energy we save today, the more carbon-neutral energy we reserve for the future.

Chris Meir is national sales manager at Remeha Commercial.