The retrofit revolution

With a high proportion of commercial projects involving replacing boilers in an existing system. Peter Gammon of Elco UK reminds building-services engineers how the use of low-loss headers and the latest boilers can smooth the way to a successful retrofit.

Under the Energy Efficiency Directive 2012, EU Member States must establish ‘a long-term strategy for mobilising investment in the renovation of the national stock of residential and commercial buildings, both public and private’ from 30 April 2014.

As a result, the UK’s Green Building Council is now ‘calling on EU nations to seize the opportunity by publishing strategies that will help ensure investment in jobs and growth, and help deliver lower energy bills for struggling European citizens.’

This all sounds very simple in theory, but in practice retrofitting buildings can be a complicated and often expensive process, especially in the replacement of commercial boiler plant.

Nevertheless, with improvements in energy efficiency important to businesses of all sizes, the demand for replacement appliances is particularly high. A large proportion of buildings will use floor-standing gas boilers for their heating and hot-water services and, as many an engineer will testify, the designs of old plant rooms can leave a lot to be desired. This presents one of the first issues for system designers who are tasked with replacing the boiler plant.

The common problem is the Δt system design conditions. Typically, condensing boilers are designed to operate with a Δt of 20 K, whereas the standard type commonly installed in the UK traditionally operate at an 11 K Δt, with flow and return temperatures of 82°C / 71°C. Installing condensing boilers in new builds presents very few concerns, but retrofitting them into a system based on traditional design practices creates a few more issues.

|

It is easy to innocently overlook differences between the existing system and the requirements expected from a replacement boiler. Taking these factors into account at the planning stage can help eliminate potential problems, and one option available to system designers is a low-loss header. This provides the ‘convertor element’ and allows traditional load circuit design conditions to be accommodated.

The low-loss header is not only employed as the interface between the boilers and the system, but it also acts as a blending device. Of course, it must be configured to handle the greater of the two mass flow rates, i.e. the secondary or load side, and the new boilers should be able to operate at a flow temperature of 91°C to achieve a suitable blended-water temperature. However, if the heat generator to heat consumer side is well matched and mass flow rates are correct, then the rest should be automatic.

Original boilers are often standard-type appliances, which are butted up close to one another other and far smaller than their modern condensing counterparts. But despite being relatively inefficient, most standard-type appliances still manage to provide the required system output from a small cubic area. Replacing them with condensing versions not only requires larger floor areas, but also added side access and clearance for maintenance purposes. In addition, as commercial buildings evolve over the years, the access to plant rooms can become difficult when replacing the plant.

As a result, some manufacturers have invested heavily in providing appliances that still produce high outputs, but are better suited to tighter spaces. These deliver an effective and energy efficient retrofit solution, which helps overcome space and Δt system design conditions.

|

| As part of Devon County Council’s commitment to reducing energy cots and carbon emissions, atmospheric boilers at New Abbot Leisure Centre have with boilers from Elcos CD range. Energy savings will provide a payback within seven years. |

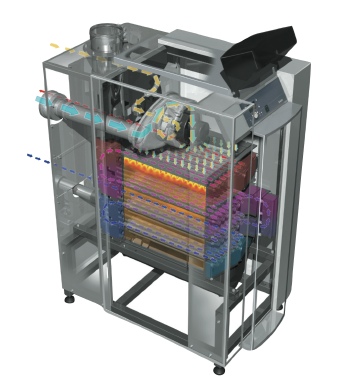

The ADI-NOx boiler range from Elco, for example, has been specifically designed to solve these difficulties with the help of an intelligent heat exchanger design. It can provide outputs of up to 905 kW, while occupying a floor area of just 1.2 m2. And, unlike many floor-standing condensing boilers, they can also be butted closely together to economically utilise floor space, operate directly with a Δt between 10 and 15 K, as well as produce exceptionally low emissions. This type of technology and system set up is already becoming extremely popular across the industry.

For projects where plantroom space is not an issue, but access is tight, building-service engineers should consider specifying boilers with a modular construction. These allow powerful floor-standing units to be disassembled into individual sections that can be transported into a plant room for re-assembly. If used singly, models such as the R600 from Elco are available with an extra-low-loss header, or a matched boiler-protection plate heat exchanger unit is available for total boiler isolation.

Investment in the renovation of the national stock of residential and commercial buildings will continue to play a key part in meeting the EU Energy Efficiency Directives. And, there is no doubt retrofitting new condensing boilers will help the UK reach the required efficiency targets. So, building-services engineers should carefully consider the potential issues at the planning stage when specifying replacement boilers for existing systems.

Such an approach will ensure aids, such as low loss headers, can be used effectively, as well as raise awareness of the latest commercial boilers which are purpose built for the task.

Peter Gammon is technical manager with Elco UK.