Pipes on the move

Des Dolan of Durapipe answers some frequently asked questions about catering for thermal movement in plastic pipes.

A common barrier to the use of plastic pipes for hot and cold water services is the perceived problematic issue of thermal movement experienced within these systems. However, the issue of expansion and contraction can be easily managed within plastic water networks if the system is designed in a way to cater for it. A number of questions need to be considered.

Do metal pipes expand and contract in the same way as plastics?

Although metal pipework also suffers from thermal movement, it is widely acknowledged that plastic materials expand and contract more than metals

Can expansion of plastic pipework systems cause problems in the pipe network?

The issue of expansion is generally only experienced with hot-water systems, but it is crucial that both expansion and contraction are addressed at the design stage of a project. Plastic pipework should always be allowed to expand and contract freely otherwise significant problems can occur. Potential consequences include at best unsightly snaking pipes, or, at worst, stress on pipe joints, potentially causing leaks in the system over time.

|

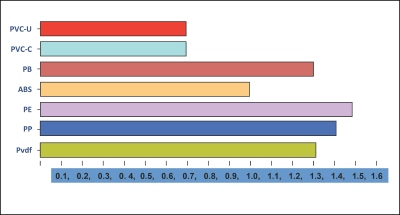

| The expansion of plastic pipe materials varies considerably. This chart shows the rate of expansion in millimetres per metre for a 10 K temperature rise. |

If it is not catered for, expansion of a pipework system can cause compression of the pipe, resulting in buckling and the risk of deformation. At the other end of the spectrum, contraction of the pipe can cause it to be tensioned again, developing tensile loads in the pipe system.

What is the rate of expansion for plastic pipes?

It is important to note that different plastic materials expand at different rates.

With hot and cold water systems, the greatest single change in temperature occurs when the pipework is first put into service, particularly if it is installed in cold conditions. For hot and cold water lines, a C-PVC system expands/contracts by 0.65 mm/m per 10 K change in temperature. If the ambient temperature is 10°C and the working temperature is 60°C, the expansion on an installed length of 10 m C-PVC pipe would be about 32.5 mm.

As you would expect, chilled-water systems work in the opposite way so while the greatest temperature change still occurs when the pipe is put into service, this is evident to a greater degree during the warmer months in the spring and summer. For chilled water lines, an ABS system expands/contracts by 1 mm/m per 10 K change in temperature. If the ambient temperature is 30°C and the chilled water is at 6°C, the contraction on an installed length of 20 m pipe will be 48 mm.

Can expansion be dealt with without purchasing additional components?

The simplest and most cost effective method of catering for thermal movement is to utilise the natural flexibility of the pipework system by building in changes of direction to the network design. The direction of pipe movement can be controlled by using anchor points at strategic positions.

Where there are no changes of direction (for example on long, straight runs) expansion loops can be installed by using 90° elbows. Another cost-effective solution, expansion loops utilise the system’s components, avoiding the need for additional mechanical fittings. However, changes in direction and expansion loops are not always a practical solution and could be discounted due to the building design.

|

| A simple change in direction enables the natural flexibility of a plastic pipework system to cope with expansion and contraction. |

Are there any situations where using the flexibility of the pipe will not work?

For applications that require pipework to be installed within restricted spaces, for example in long straight runs along narrow corridors, utilising the flexibility of the pipework will sometimes not be possible, and linear expansion devices will need to be used. In such cases, contractors and consultants should always look for a pipework system that incorporates an expansion device, as ranges that offer a fully integrated solution will be more cost effective than purchasing a pipework system and expansion fittings separately.

What other options are available for dealing with thermal movement?

If separate expansion devices are needed, the main options are expansion compensators, bellows and flexible hoses. These need to be monitored at regular intervals, so they must be accessible. It should be possible to inspect, dismantle and replace parts without disturbing other elements of the system.

Flexible hoses are typically used on smaller-diameter pipework, and it is critical that the expansion joint is not subject to twisting during installation or operation in order for it to remain effective.

Another alternative is purpose-designed expansion compensators dedicated to particular plastic-pipe systems. This type of fitting needs to be fixed in position so as to take up any expansion and contraction, utilising a sliding component within the body of the fitting.

The most costly option, bellows, is generally used on larger-diameter sizes. Bellows are available in a variety of different materials, and it is important that the selected fitting is compatible with the specific plastic pipe material it is being connected to.

Des Dolan is Durapipe’s building-services brand manager.