Balancing air quality and energy efficiency

Particulates are one of the main pollutants in air, both outdoors and indoors. Removing them can be an energy-intensive process. Tom Winsper of Vokes Air looks at the issues to be considered.

|

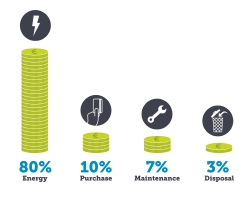

| 80% of the cost of air filters is due to their associated energy consumption. |

Particles such as soot, smoke, liquid contaminant, dirt and other dusts are all classified as particulate matter (PM) and categorised according to their diameter in microns (µm).

• PM10: 10 µm and less. They are typically caught in the throat.

• PM2.5: 2.5 µm and less. They are trapped in the lungs.

• PM1: 1 µm and less. They enter the bloodstream.

It is the finer particulate less than 10 µm in diameter that poses the biggest health risk. In fact, a UK Government report found that even reducing the level of PM2.5 in the atmosphere would be more beneficial to life expectancy than eliminating traffic accidents and passive smoking combined.

HVAC air filters provide the defence against particulates that evade our body’s natural defences. Classified according to their effectiveness at stopping particulates, there is a real change in performance across the classes, particularly when it comes to the finer PM2.5 dust (Table 1). With this in mind, the importance of choosing a level of filtration that provides sufficient protection against such contaminant is clear.

The underlying predicament of this situation, however, is that a filter system’s energy consumption increases proportionally to its filtration efficiency. So whilst simply raising the filter class will improve the air quality, it will do so at an increased energy cost.

Energy efficiency

A filter consumes energy by presenting a resistance to the air that flows through it. This pressure drop means that the ventilation fan has to work harder to move the air. The speed required is related to the power consumed by the fan motor according to a cube law. Put simply, if the pressure drop over the filter is lowered by 10%, the fan speed drops by 10% but the power consumption falls by nearly 30% (0.9 cubed = 0.729).

| Filter Class (EN779) | PM2.5 Removal | PM10 Removal |

| M5 | 35% | 80% |

| M6 | 55% | 85% |

| F7 | 80% | 90% |

| F8 | 90% | 95% |

| F9 | 92% | 97% |

In terms of the total costs associated with operating a filter, energy plays an equally significant role. Depending on the system, the purchase price of a filter will typically be just 10% of the total cost associated with its operation, with energy accounting for 80%. That’s why it is imperative to focus on reducing the energy demand of a filtration system.

Air filters with lower energy consumption often have a higher purchase price than the more basic options on the market. Better products have a higher price tag. But as energy represents such a large proportion of the costs associated with running an air filter, the option that is more expensive up-front may well be cheaper in the long-run.

Fortunately, the independent trade association Eurovent operates an energy-rating scheme for air filters. The scheme ranks eligible products according to their energy efficiency from A+ (the best) to E (the worst). All participating manufacturers must display the energy performance of rated products in their marketing literature and product labelling, so choosing an efficient filter is that much simpler.

|

| Improved filtration performance comes with an energy premium. |

However, what this programme also highlights is the difference in energy consumption between the different filter classes. For example, an A-rated F8 filter will consume nearly twice as much energy as an A rated M6, so simply choosing a product with an A or A+ rating will not guarantee energy efficiency.

Other factors also play a part in energy efficiency. Replacing filters on time is crucial, for example. A clean filter will account for around 25% of an HVAC system’s energy consumption. A dirty filter increases this value to 50%. Incorrectly sized or improperly configured filters can have a dramatic effect on efficiency too, so it is important to check the specification of the filters in your system.

Finding the happy medium

The key to optimising the air-delivery system is to choose an energy-efficient filter in the correct filtration class. But how do we determine what is the correct class?

The World Health Organisation currently classify acceptable levels of PM10 and PM2.5 as 20 μg/m³ and 10 μg/m³, respectively. By using the particulate removal rates detailed previously, it is relatively straightforward to calculate what filter class is required to achieve these safe levels. The difficulty is establishing the level of contaminant present in the immediate environment.

Fortunately, DEFRA (Department for Environment, Food & Rural Affairs) has over 120 monitoring stations dotted across the UK, which give an overview of the external environment — but the smallest particulate, PM1, is not measured (Table 2).

Considering the figures in Table 2, it makes sense that Cardiff should not require a filtration class as high as that needed in London. The level of contamination is simply nowhere near as high.

| PM10 µg/m3 | PM2.5 µg/m3 | |

| Glasgow | 20.4 | 19.3 |

| Newcastle | 17.0 | 10.4 |

| Manchester | 16.7 | 12.5 |

| Birmingham | 22.6 | 13.2 |

| Cardiff | 18.0 | 12.1 |

| London | 31.3 | 22.9 |

| Southampton | 19.4 | 14.3 |

| Plymouth | 19.7 | 10.6 |

It must also be remembered that these levels are averages. The figure for London is taken from the Marylebone monitoring station, which recorded PM levels in excess of those listed for 40% of the time, so a safety factor must be built into the analysis.

Of course, a monitoring station, no matter how local, cannot provide an exact picture of a building’s dust ‘challenge’. Construction works, heavy industry, exposure to seasonal pollution such as high pollen counts, all have an impact, and provision must be made when determining the input dust count level. Even in a single location, some air-handling units may face different challenges, such as proximity to loading bays where exhaust fumes are present.

This may seem like overkill for a simple air filter, but the rewards for getting it right are high. An energy-efficient system will provide considerable cost savings, and the optimum filtration level will provide protection to building occupants. Your air-filtration supplier should be able to assist in the analytical process.

Tom Winsper is marketing and communications manager with Vokes Air.