Combining indoor air quality and energy efficiency

In response to the challenges of ventilation for commercial buildings, Robert Dennis of Airflow Developments looks at the key issues to consider and the innovative solutions that can save valuable time, energy and costs — whilst creating a healthy interior environment.

The European Commission recently released its first joint strategy on heating and cooling, which is a result of recognising the need to tackle air pollution, energy wastage and the amount of greenhouse gases released into our atmosphere. According to the strategy, if we act now to reduce greenhouse gas emissions, over €3.9 billion could be saved and 5700 deaths per year related to local and regional air pollution could be prevented.

Urbanisation and climate change are just two factors that are driving air pollution in the wrong direction. To tackle this and achieve 2050 emission targets, as well as reduce energy consumption, there has been a significant focus on how buildings are constructed and refurbished. Improved build quality has resulted in increased insulation and air-tightness of buildings, which is great for the environment and minimising outdoor air pollution. However, it is not good news for indoor air quality.

Although most airborne pollutants cannot be seen or smelt, their effects can be dangerous — with major health conditions such as cancer, asthma, heart disease and obesity all being linked. Cognitive functions have also been shown to be adversely affected by poor air quality.

A sealed building without the necessary ventilation is more susceptible to damp, mould and condensation, which can cause damage and unsightly marks to the fabric of the building. Such damage can be costly and time consuming to repair.

Those responsible for the management and maintenance of commercial and industrial premises therefore have a duty of care to ensure adequate ventilation is in place.

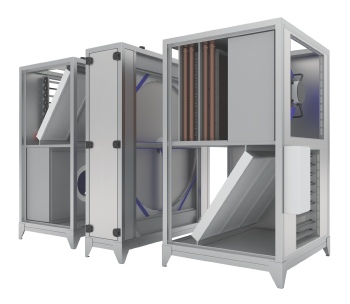

|

| Thermal wheels are an effective method of heat recovery in large AHUs |

The future is mechanical ventilation with heat recovery (MVHR).

Ventilation systems that not only extract stale, unhygienic air but also filter in clean, unpolluted air whilst lowering the environmental impact of commercial or industrial buildings are the logical specification.

MVHR systems extract the stuffy air from inside a building and reclaim the heat from this air via a heat exchanger, which then pre-warms the incoming clean, fresh air that is constantly brought in from outside and circulated within the building. At no point do the airstreams mix. MVHR units recover heat that would normally be lost as part of the ventilation process to, as a result, reduce heat and energy wastage.

There is a vast range of MVHR solutions available to meet the varying requirements of all commercial buildings. For example, Airflow’s Duplexvent commercial heat-recovery range provides ventilation with heat recovery for all types of commercial and industrial premises. Highly efficient cross counter-flow polypropylene exchangers extract the heat from warm exhaust air and transfer it to the incoming filtered, fresh air, reaching up to 95% thermal efficiency. This can translate into a 40% saving on heating costs.

During the summer when heat recovery is not required, the heat exchanger can be bypassed to help prevent overheating within the building by not warming the supply air unnecessarily, helping to keep indoor air temperatures and humidity conditions at a stable and comfortable level.

MVHR units with a thermal rotary-wheel heat exchanger can also help improve the energy performance of a building. The heat exchange process is most efficient when the air streams flow in opposite directions, as this causes a favourable temperature gradient across the body of the wheel. The Duplexvent Rotary range uses a thermal wheel, that can achieve up to 85% heat recovery and deliver air volumes of up to 16 000 m3/h.

|

| The counter-flow heat exchanger in this MVHR unit can achieve up to 95% thermal efficiency, thus reducing heating costs by up to 40%. |

As buildings become more insulated and less penetrable to the outside environment, it is important to consider the noise output of ventilation systems, as sound coming from inside the building will be more noticeable. Ventilation units that are powered by low-energy EC fans are not just extremely quiet, but can also provide significant energy reductions.

Effectively controlling the ventilation system is also a prerequisite for an energy-efficient building. Without controls that are correctly set up and used, a building can never achieve its maximum efficiency. Therefore, those responsible should look to specify systems that include a built-in Internet or BMS connection. This allows technicians to connect to the unit from a remote location and will give those responsible the ability to continuously check the status of any unit — preventing system downtime and reducing the need for on-going maintenance.

Guidelines dictate there should be a supply of fresh air of 30 to 36 m3/h per person in commercial buildings. Rather than just supplying recycled air as seen with older ventilation systems, it is important to guarantee the constant supply of fresh air, as seen with modern MVHR systems. In addition, ventilation units should have an inbuilt filtration system to clean out airborne particles such as dust, pollen and mould spores.

Those seeking heat- and energy-recovery ventilation solutions for commercial and industrial premises should gain specification advice from a leading manufacturer. In turn they will benefit from the most effective ventilation solution, which will achieve a healthier internal environment, help protect building fabric from damage and reduce running costs —whilst being energy efficient and environmentally conscious.

Robert Dennis is product marketing executive at Airflow Developments.