In your comfort zone

All engineers face the challenge of maintaining a comfortable internal environment while also ensuring the building services are energy efficient. Paul Wightman considers how this can be achieved with modern heating systems.

Comfort remains one of the most elusive goals of the building services industry. Each individual person’s perception of comfort is totally unique and a single degree’s fluctuation higher or lower on the thermometer can quickly spark debate about it feeling too hot or too cold.

Comfort is entirely subjective and virtually impossible to measure. However, it is generally the swings in temperature that cause the most discomfort. For HVAC engineers working in office environments and other public buildings, limiting these fluctuations and striking the right balance in the heating system is fundamental to the wellbeing of the workforce and in creating a stable, trouble-free system.

|

|

Differential pressure control valves (DPCVs) help to stabilize the temperature in heating systems. |

The correct design and accurate implementation of central heating and chilled water (CHW) systems will provide the right balance for optimum comfort levels and effective temperature control all year round.

Heating systems in public spaces such as office blocks, retail outlets, hotels, hospitals and schools come under much stress, with multiple variants potentially compromising the smooth running of a system.

Heating systems in commercial buildings must be designed to accommodate the movement of people, the use of electronic appliances, open windows and doors, and potentially individuals tampering with thermostatic controls.

A combination of all these factors contributes to an environment, which can be either too hot or too cold, with draughts and often with not enough ventilation. They also cause huge inefficiencies in the heating system.

In a work environment, poor temperature control can have the knock-on effect of poor performance, and both overzealous use of heating as well as icy blasts from CHW units can be equally troublesome and uncomfortable for a workforce.

In order to promote a occupant wellbeing, the focus for heating engineers should be on balance and control.

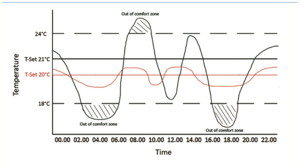

In engineering terms ‘T set’ is the desired room temperature we wish to be controlled exactly and perfectly at all times of year and throughout the day.

With poor balance and control, the system swings become too great, which causes extreme temperatures in our environment and energy wastage.

|

| HVAC engineers work hard to achieve the balance of heating and cooling. |

A correctly balanced variable volume system can only be achieved with the correct set of dynamic balancing and control valves. These ensure the correct distribution of flow throughout the whole system, irrespective of any pressure changes or the partial loads that will inevitably occur for the vast majority of the building’s operational life.

If the correct balancing of the system is not established, this will result in unequal distribution of the flow, so that there will be a surplus effect in some of the terminals, while not enough in others, lowering the quality of the internal enviroment or comfort control.

The result of this will be that the desired heating or cooling will not be ensured in all parts of the installation.

One solution is the use of differential pressure control valves (DPCVs) which has proved to be extremely efficient in helping to stabilize the temperature in heating systems.

Consider a 2-pipe radiator installation for example, in a localized area of a typical commercial building. The installation may include anywhere from 5-20 radiators, radiant panels or similar such emitters in this circuit on any given branch pipework. Similar circuits will be frequently repeated throughout a large commercial building.

Including DPCV units in a circuit creates a robust system that not only simplifies commissioning as each DPCV-controlled circuit and can be balanced in isolation, but also allows for future expansion and phased installation without the need for re-commissioning, which would be necessary with traditional static balancing.

| In the zone |

|

The diagram shows how in a conventional system, the engineer is trying to maintain T-set of 21° C. When control is poor then the band either side may be significant in this example +/- 3°C. |

|

|

The red area shows improved control where the set-point is lowered by 1°C. Since the control band is narrowed, comfort is achieved in an energy efficient way. The message is that if we never overheat an area, then the chances of discomfort caused by a lower temperature are less pronounced and not as likely to cause problems and complaints from occupants. |

The thermostatic radiator valve (TVR) is another essential component in such a system. With a temperature sensor head, it is designed to reduce and eventually shut-off flow to the radiator when the temperature reaches set point. It is apparent that in each circuit, when this temperature control happens, with all other conditions remaining the same, differential pressures will increase.

TRVs come with lockable tamper-proof temperature settings ideal for commercial environments. In addition, a pre-setting valve position allows individual radiator or emitters to be flow-set at the design stage so reducing installation time by eliminating the cumbersome and time-consuming lock shield valve commissioning approach.

With a traditional static balancing valve approach this increase in pressure will not be controlled, so more flow will occur in the branch causing wasteful overflow on those radiators.

Variable speed pumps will support speed reduction and subsequent differential pressure lowering. This regulation is only local to the pump, which must always deliver sufficient performance for the index circuit. The index circuit position changes within variable volume designs to the extent that the absolute pump regulation within all sub-circuits is impossible and a degree of over pressure is inevitable.

The DPCV inclusion removes these pressure fluctuations, so enabling all TRVs within the DP circuit to maintain good temperature control as the differential pressure across them is relatively stable irrespective of other circuit’s control valve operations or VSD pump speed changes.

Similarly, in installations that require balance to be controlled in a specific location, e.g. one point of delivery to a room, pressure independent control balancing valves (PICV) can be used. These are particularly effective on 4 pipe HTG & CHW terminal units such as fan coil units (FCUs) and air handling units (AHUs), that can overheat the space or emit chilly blasts when over-circulating chilled water in the system.

Paul Wightman is technical specification manager for Albion Valves.