Keep your standards high

Chris Davis highlights the importance of HIU performance and sizing for heat networks, and looks at standards for ensuring that specifiers and end users know what they’re getting.

So how does heat interface unit (HIU) performance and sizing impact on heat network efficiency? The truth is it has a major impact, both with respect to return temperatures and network sizing. Recent studies have shown that even a single poorly specified HIU could be responsible for the underperformance of an entire network.

Problems such as poorly controlled valves and oversized plates are often seen, and where units do perform badly it is very difficult to limit primary return temperatures and for the heat network to deliver the expected level of carbon and energy cost savings.

BESA standard for HIUs

With all of this in mind, BESA (the Building Engineering Services Association) launched a UK standard for heat interface units in 2016. This was developed by industry experts including representatives from FairHeat, Carbon Alternatives, CIBSE, BESA, BEIS, Engie, E.ON

The standard is regarded as an important step towards improving the overall performance of district heating schemes. Its key objective is to enable the performance of different HIUs to be evaluated within the context of typical UK operating conditions, enabling heat network developers to consider the performance of specific HIUs against design requirements.

|

|

Table 1: BESA VWART results for the ModuSat XR-ECO |

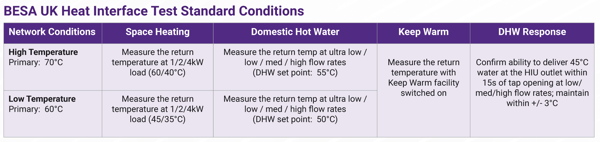

Individual heat interface units are independently tested against the criteria shown in the table below, which represents typical UK heat network operating conditions, and includes tests to measure performance at part and full load.

The outcome from the first three tests is used to calculate a volume weighted average return temperature (VWART) for each HIU at standardised high temperature and low temperature network conditions. As the name suggests, this is intended to provide specifiers with an indicative weighted-average return temperature from the HIU over the course of the year. It takes into account typical operating profiles for space heating, water heating and with/without ‘Keep Warm’ (if the unit has the ability to switch Keep Warm off).

A lower overall VWART represents a lower average annual return temperature from the HIU to the primary network and therefore a better performing HIU. Table 1 shows published BESA VWART results for the ModuSat XR-ECO at high temperature test conditions.

Units that are tested according to the BESA regime will not be certified, but the results are published in the public domain and freely available from the BESA website, enabling comparative performance to be evaluated within the context of typical UK heat networks in new build flats and apartments.

|

Keep Warm facility

One of the key impacts on the overall VWART figure is the use and control of the ‘Keep Warm’ facility, which is designed to keep the risers and laterals warm continuously so that the HIU’s can provide a fast response as soon as there is demand for domestic hot water. Without keep warm, HIU’s would need to bypass lots of low temperature water while the primary comes up to a comfortable temperature for the resident, wasting water and energy.

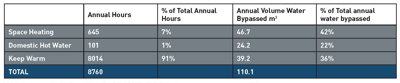

For the BESA test regime, the Keep Warm VWART figure is calculated using a weighted average that assumes Keep Warm is switched on for an average of 90% of the year (i.e., constantly available while the HIU is not producing space heating or hot water). And while the Keep Warm facility should only ever bypass a small volume of water per hour, the proportionately high number of annual hours that an uncontrolled Keep Warm bypass might be left on can add up to a significant amount of warm water being bypassed back to the network over the course of the year - wasting energy; raising the primary return temperature; and reducing the delta T, as illustrated in Table 2 above.

As can be seen, despite the Keep Warm being temperature controlled (in this case), the Keep Warm facility is still potentially responsible for over a third of the annual volume of water by passed back to the primary network.

|

|

Table 2: Example: Evinox ModuSat® XR-ECO, BESA high temperature test conditions |

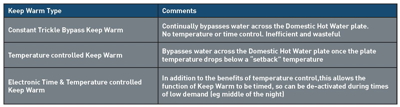

We find that different HIU manufacturers approach Keep Warm in different ways, typically we see the methods in Table 3 for UK heat interface units.

The efficient solution is to provide both time and temperature control over Keep Warm. By allowing the keep warm to be timed, it can be deactivated during periods of low demand (eg middle of the night), something which is only possible with electronically-controlled HIU’s. Some models allow this control to be managed either by individual residents or managed globally across the network by the operator as the Keep Warm time and temperature settings can be remotely adjusted.

This means that actual average annual return temperatures can be further reduced, with a suitable balance between the speed of DHW delivery for the home owner and the overall network efficiency requirements of the operator.

|

|

Table 3: Different approaches to the Keep Warm facility |

Until now, it has been a common misconception that HIUs are one size fits all, but results from the BESA tests show that this isn’t the case for today’s systems. The network design and HIU specification must be closely matched to ensure optimum performance and the HIU must deliver the widest delta T and lowest return temperatures possible in all operational modes.

The BESA standard is an important step forward for the UK’s district and communal heating market, and although it is currently optional, Evinox believes this will be a mandatory requirement in the near future. Certainly, we are already seeing designers and specifiers starting to insist on the use of BESA tested units for their heat network projects going forward, something that can only be a positive step for the sector.

Chris Davis is head of sales and marketing at Evinox Energy.