The balance of choice

With the demand for pressure-independent balancing and control valves accelerating comes the need for comparing their performance and capabilities, as Stephen Hart of Frese explains.

In an effort to increase energy efficiency of water-based distributed heating and cooling systems, also referred to as hydronic systems, building-services designers have largely adopted variable-speed pumps and 2-port control of room terminal devices.

However, pressures within such systems can fluctuate dramatically during operation, and the industry has responded by introducing pressure-independent balancing and control valves that can absorb these fluctuations in system pressure and maintain the system in balance — even in part load. The adoption of this new technology has been surprisingly rapid, even to those who have been convinced of the benefits of the dynamic balancing of hydronic systems for many years.

|

| Fig. 1: Frese’s production of pressure-independent valves has accelerated in the last few years, and the cumulative total now exceeds 2.5 million units. |

It might appear to some that the rapid and widespread implementation of pressure-independent flow and temperature control is revolutionising the design of variable-flow hydronic systems. However, for Frese and one or two other manufacturers from both sides of the Atlantic, this ‘revolution’ has taken more than a quarter of a century to develop and has only accelerated in the last few years as the reality of carbon-reduction commitments and the fuel cost of inefficient heating and cooling system has started to bite (Fig.1)

Indeed, the Frese pressure-independent range of valves has evolved over the last 25 years and the latest generation of Optima Compact pressure-independent control valves is our third generation of PICV technology. Whilst each generation of technology has delivered enhancements and features over the previous one, the accumulation of knowledge regarding the application of the technology within the wider hydronic system has been continuous over the period. The overall product performance that leads to customer satisfaction requires a wider knowledge of how to design, commission and troubleshoot hydronic systems incorporating pressure independent valves.

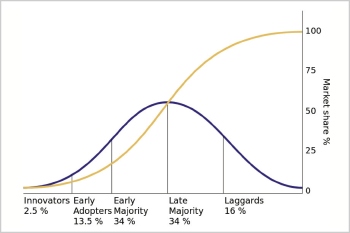

Fig, 2 illustrates the diffusion of innovations according to Everett Rogers, a professor of communication studies, and popularised in his book ‘Diffusion of innovations’ way back in 1962. With successive groups of consumers adopting the new technology (shown in blue), its market share (yellow) will eventually reach the saturation level.

It appears that the innovators and early adopters have decided that pressure-independent balancing and control valves are the best way to dynamically balance hydronic systems.

|

| Fig 2: The take-up of pressure-independent control valves has reached the early-majority stage of market evolution. |

It now appears that the early majority is on the move, New market entrants into the PICV business are increasing as rapidly as the demand for these products. This is a risky time for the established manufacturers, as inexperienced manufacturers are required to deliver a product to the market that, due to increasing competition or the need to avoid existing patents, may risk the reputation of not only the product or manufacturer in question but the technology as a whole by releasing an inferior product.

It might seem to some that including a PICV in a hydronic system design is the latest fad rather than a balanced decision based upon the pros and cons of the technology and viable alternatives available on the market. It might also seem that the final selection of which product to use has been based upon which manufacturers’ sales representative had the best sales pitch or which product was most easily available at the lowest price!

At a time when the industry is learning to use these products correctly and establishing the benefits and pitfalls of applying the technology, the need for an objective assessment of the products available on the market is critical. Unfortunately, not all pressure-independent flow and temperature control valves deliver the same performance. With a few noticeable exceptions, specifiers and installer lack the knowledge to tell the difference before the buying decision is made and the products are installed.

There is currently no performance standard for pressure-independent balancing and control valves although a number of manufacturers are pursuing this goal under an eu.bac initiative which may also deliver an energy-performance rating scheme for the technology.

|

| Fig 3: An important feature of the performance of PICVs is repeatability as flow conditions change. |

In the mean time, a number of manufacturers have supported the development by BSRIA of a test standard for pressure-independent control valves that will allow specifiers to compare the performance of different products, benchmark them against one another and determine their suitability for any given application. Once the valves’ authority, turndown, let by leakage, repeatability (Fig. 3), hysteresis and pressure independence are known, the specifier can make an informed decision over the relative cost and benefit of each product.

It is clear that the better informed the user of the benefits and limitations of each product, the more likely the actual experience of using pressure-independent balancing and control valves will live up to the promise and expectation. This is in everyone’s best interest — especially the manufacturers.

Stephen Hart is managing director of Frese Ltd.