Taking control of frost build-up

The build-up of frost on the outdoor coils of air-conditioning systems in heating mode can interrupt the provision of heating and use a significant amount of energy to melt it. Neil Wooldridge of Toshiba Air Conditioning explores the issue.

All air conditioning systems are subject to frost build-up on their outdoor heat exchanger when in heating cycle. Paradoxically perhaps, frost is a very effective insulator and the reason an igloo can make a cosy shelter from extreme outside temperatures.

While the insulating properties of frost and snow may be good for Eskimos, they present a serious problem for the performance and efficiency of air-conditioning systems.

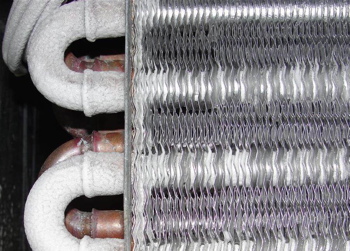

The bottom line is that frost build-up on the cold surface of heat exchangers significantly reduces system efficiency. Bare aluminium and copper provide excellent thermal-transfer characteristics. However, it is not long before water vapour in the air passing over the cold surface reaches dewpoint and is deposited and gets frozen, resulting in a dusting of frost.

At this point, unless active steps are taken, frost build-up will continue to accumulate to perhaps many inches in thickness, rendering the refrigeration system ever more inefficient and ineffective.

To overcome this, and restore cooling performance, frost must be regularly removed through the application of energy. Depending on humidity levels in ambient air and temperatures, the defrost process has to be repeated a number of times each day.

Energy for the defrost is traditionally obtained from so-called hot gas, via the refrigeration system. In normal cooling mode, this harnesses heat that would normally be sent to the condenser for ejection to the environment to melt frost on the heat exchanger, and return the system to full performance.

|

| Defrosting coils before too much ice builds up is crucial to maintain heating performance. |

In reverse-cycle heating mode, frost builds up on the outdoor coil, affecting the performance of the indoor system and limiting its heating capacity. For obvious reasons, this is a particular issue when ambient temperatures are low and the requirement for heating high.

The standard way of clearing such frost build-up in is to reverse the cycle for a short period, so that the hot gas passing through the heat exchanger melts the frost on the outdoor unit and restores full operation.

The problem with this approach is that while the building is calling for heating it involves putting indoor units into cooling mode. To prevent cold air from entering the indoor space and chilling occupants, fans on indoor units may be temporarily switched off during the defrost. This might typically last 8 to 12 minutes, with the defrost cycle itself being repeated every hour or so.

This is only a partial solution, therefore, because while the defrost progresses, heating into the space is suspended. If conditions outside are particularly cold, this could lead to rapid fall of indoor temperatures and potential complaints.

So-called phase-change defrost systems have been tried in the hope of improving the speed and effectiveness of the defrost process. However, some require quite significant additional energy inputs to maintain their thermal charge. If permanently in circuit — as they need to be to work — this can incur a quite large energy penalty.

Recognising the problem, Toshiba has developed an approach to the perennial defrost problem that overcomes the traditional downsides. It involves the use of a by-pass system with diverter valves to send pulses of very hot gas (at around 70°C) produced in the normal refrigeration cycle to outdoor units, to deliver a powerful and quick flash defrost.

Importantly, this is carried out before frost reaches a ‘hard’ frozen state, while frost is just forming and is in a soft, so-called ‘blue state’. This requires significantly less energy to melt than hard frost, and cuts the defrost time to an average of two minutes.

During research and development it was found that in normal conditions, defrosting blue ice was sufficient to keep the system operational, with the key benefit of its inherent energy efficiency and maintaining continuous heating to the building. However, if required, the system can initiate a full reverse-cycle defrost.

|

Building on this concept, Toshiba’s SHRM-e VRF system incorporates a control that continually monitors the status of the outdoor coil. When it senses the outdoor coil is beginning to frost, the hot gas by-pass operation initiates, melting any frost build-up and allowing the indoor units to continue to heat, with only a small reduction in capacity.

With regard to energy efficiency, Toshiba’s published energy-performance figures include and take account of the operation of normal defrost cycles. This is not universally the case among manufacturers; some exclude energy consumed by defrost systems in calculations of efficiency performance, with defrost systems out of circuit as the default condition upon equipment delivery, and requiring manual intervention to actively switch them in.

Even accounting for defrost, Toshiba achieves an ESEER (European seasonal energy efficiency rating) above seven for every unit in the range.

Neil Wooldridge is technical manager with Toshiba Air Conditioning.