Air distribution is the key to good indoor air quality

The vast proportion of complaints attributed to indoor air quality are the result of poorly designed or inadequate air distribution. Alan Green, Ian Thomas and Mike Gosling discuss the issues against the background of new guidance from the HEVAC air-distribution group.

Our building interiors were once thought of as providing a safe haven from the effects of increasing outdoor air pollution and changing climates, but they may actually be more polluted than the surrounding ambient environment.

With the implementation and continual tightening of UK regulations for airtightness of buildings, the need for improving indoor air quality and well-designed ventilation systems is becoming increasingly important as the exchange of heat and pollutants can no longer take place naturally through the building fabric.

The term ‘indoor air quality’, or IAQ, is commonly used to define the quality or cleanliness of the air within an enclosed, occupied space. However, its effects are far reaching as it can influence not only the health of occupants but also their perception of comfort and ultimately can determine their productivity.

Whilst technology has advanced significantly in recent years within sectors directly affecting the cleanliness of ventilation air (e.g. improved filtration/control within AHUs, improved monitoring and adoption of ductwork cleaning), the job of the air terminal device (ATD) has been taken for granted. However, the importance of the role of ATDs in distributing ventilation air effectively should not be overlooked as the vast proportion of complaints attributed to IAQ can actually be as a result of poorly designed or inadequate air distribution.

|

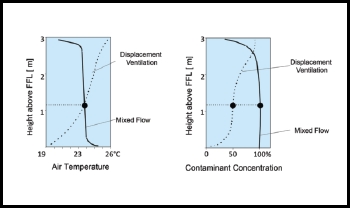

| Fig. 1: Displacement ventilation offers better local IAQ for occupants than mixed flow but has significant limitations in terms of cooling capacity. |

As an example, excellent distribution of air within a room can compensate to a large extent for a minor deficiency in cooling capacity, but no level of excellence in the cooling or air-supply systems can compensate for poorly designed room air distribution.

The HEVAC air-distribution group, whose members represent the leading manufacturers within the ATD sector, have released an update to its ‘Guide to air distribution for the internal environment’ to help building designers, owners and operators understand the different approaches that can be used to produce the optimum internal environmental conditions.

The correct selection of ATDs is necessary to ensure that occupant comfort and adequate ventilation mixing are achieved, both of which directly affect a person’s perception of IAQ. An example would be a well-designed space, with air being supplied comfortably with both temperature and airspeed within acceptable limits. However if the air discharge does not cover the full zone, a build-up of contaminants and a feeling of stuffiness can be experienced. This can be accentuated in areas subjected to varying load profiles (such as perimeter and internal zones) where different strategies are required to ensure conditioned and ventilated air is effectively delivered to the building occupants.

There are two main approaches used for air distribution.

• Mixed flow: This is most common method of air distribution used in the industry. Conditioned air is supplied at high level using diffusers designed for high induction and rapid mixing of supply air — thus diluting surrounding stale room air. This rapid induction and mixing of supply air results in an even distribution of temperature and airborne contaminants throughout the zone. With high-level high-induction supply air, the temperature of the supply air can be 10 K below that of the room air to offset high heat gains (up to 180 W/m²) with minimal airflow rates.

• Displacement flow: With this type of flow, conditioned air enters through low level ATDs and spreads across the floor to form a reservoir of fresh cool air. Local heat gains within the zone create a thermal plume rising upwards and entraining the surrounding fresh air. By this means the fresh air is continually replenished as contaminated air is lifted to a higher level and extracted. The resulting stratification of temperature and contaminant levels (Fig. 1) result in significant improvements in IAQ when compared to mixed-flow ventilation However, as the air is introduced at low level, the temperature of the supply cannot be more than 5 K below that of the room air, restricting its cooling capacity to a maximum of about 40 W/m² for comfort. In semi-industrial application and locations with transient movement of people capacities of up to 60 W/m² can be used (Fig. 1)

|

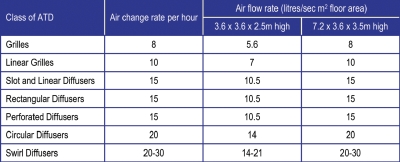

| Fig. 2: The HEVAC guide provides information on the different classes of air-terminal devices and recommended guidelines for maximum air-change rates. |

The effects on temperature and contaminant concentrations between mixed-flow and displacement flow can be compared in Fig. 1. To summarise, displacement ventilation offers better local IAQ for occupants than mixed flow but has significant limitations in terms of cooling capacity.

To provide guidance on the correct selection of ATDs, the HEVAC guide provides information on the different classes of ATD and recommended guidelines for maximum air-change rates (Fig. 2)

The key to achieving optimum ATD selection is early collaboration between the design team, with the experience offered by specialist manufacturers who can guide the most appropriate ATD selection to suit the project specific environmental parameters.

A zone-by-zone analysis is almost always prohibitive in terms of design time and probably not necessary for most spaces. Internal open office spaces, which are typically in cooling mode all year round, can usually be characterised in a general way and excellent diffuser selections made for these locations.

Perimeter zones are more complicated, with both thermal and aerodynamic issues to be considered, However, these can often be characterised in a general way for the building design, and excellent air distribution can be achieved.

As diffuser selection can range from the selection of a ‘hole cover’ (or ‘architectural duct termination’) to a detailed analysis of the diffuser air-supply pattern in each zone, it is crucial that the ATD manufacturer can offer support from initial design and product testing through to installation to ensure the final solution meets with the increasing expectations of IAQ.

Alan Green and Ian Thomas are members of the HEVAC air distribution manufacturers group and with Trox UK. Mike Gosling is with Trox UK.

To download the guide see link below.