Air control as the key to energy-efficient labs

Laboratories with fume cupboards can benefit from demand-controlled ventilation — with major savings on the volume of air handled and conditioning it. Ian Thomas of Trox UK explains.

The international reputations of universities frequently rely on the quality of their laboratory-based research, but these achievements come at a cost. In addition to the specialist equipment needed for lab-based research, there are accompanying financial and environmental burdens. With energy consumption between three and four times higher than other teaching areas, laboratory buildings are responsible for between 50% and 80% of the total energy-related (non-residential) carbon emissions of research-intensive universities.

Reducing the energy consumption of laboratories presents particular challenges. Health and safety is paramount, and the integrity of research outcomes relies on the maintenance of the correct environmental conditions.

There are a number of valuable approaches, however, that can reduce energy costs, improve sustainability, and provide better air management in laboratories without compromising on health and safety.

|

The harnessing of variable-air-volume technology, in particular, offers significant potential to reduce energy consumption by preventing over-supply and over-extraction of conditioned air.

Much of the increased energy consumption in the laboratory relates to the use of fume cupboards.

When sashes are open, the volumes of air required to maintain a safe working environment for the laboratory personnel increase significantly. For example, a 900 mm-wide cupboard with a maximum sash height of 500 mm and face velocity of 0.5 m/s would extract approximately 225 l/s. This figure would be fixed on a constant volume cupboard, whereas on a variable-volume cupboard the minimum air volume could be around 55 l/s when the sash is down.

Converting from constant volume to variable volume would save 170 l/s when the sash is in the down position for a single cupboard. As this air has been conditioned, using energy-consuming chillers, fans and perhaps dehumidifiers, this has implications for energy efficiency.

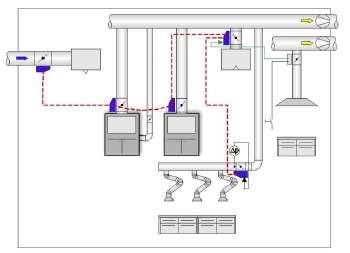

Room air-management systems are proving an increasingly popular option for improving energy efficiency of laboratories as they automatically control all input and extract air for the laboratory. This ensures that the required ventilation strategy is maintained, and the room balance (and therefore operator safety) is controlled automatically. All devices are connected locally (within the room) by a digital network (Fig. 1). There are three airflow drivers.

|

| Fig 1: Connecting all devices in a laboratory by a digital network opens up a host of control possibilities. |

• The number of air changes necessary to meet the safety requirement.

• The supply air required for cooling/heating the laboratory to a comfortable temperature for occupants.

• The supply air needed to replenish air exhausted by fume hoods.

A room air-management system such as Trox’s EasyLab system manages the supply and extract controllers so that they respond rapidly to changes in extract volumes by the technical extract (that is, the fume cupboards) to ensure the correct air-flow balance and room pressure at all times. This approach to lab air management has a significant impact on energy efficiency, as it prevents unnecessary supply of conditioned air to the space.

Room air-management systems have the added advantage of offsetting one form of exhaust air against another. For example, if the fume cupboards are open and extracting air, there is not the same requirement for the room system to carry out this process.

By scaling down of room exhaust air extraction in line with fume-cupboard extraction, the room air-management system can prevent over-supply and extraction of conditioned air from the space. EasyLab’s automatic exhaust air optimisation feature, for example, will enable the room-extract VAV unit to close when the required room air change rate is being met by the fume cupboards or other technical extract in the room. This further reduces the total extract volume.

|

| Trox’s EasyLab system manages supply and extract controllers so that they respond rapidly to changes in extract volumes by fume cupboards to ensure the correct air-flow balance and room pressure at all times. |

It is also possible to improve energy efficiency significantly by tailoring systems more closely to working patterns. These approaches could include systems for sensing and closing sashes of fume cupboards when they are not in use or rethinking air-change rates in some low-risk laboratory areas, or at times of the day/week when laboratories are unattended.

There are also numerous options for local cooling or extraction that can deliver energy savings, such as ventilated down-flow tables, canopy hoods or fume exhaust ‘snorkels’ that may offer more effective cooling or air management. It is also worth remembering that upgrading the control technology of existing fume cupboards can be an effective solution.

Ian Thomas is product technical manager — air products, Trox UK.