CUTTING THE COST OF INACTION

By Andrew Boothroyd, Energy Upgrade and Service Director, Armstrong Fluid Technology

As we head into a new year, it is time to rethink how energy upgrade projects should be managed.

|

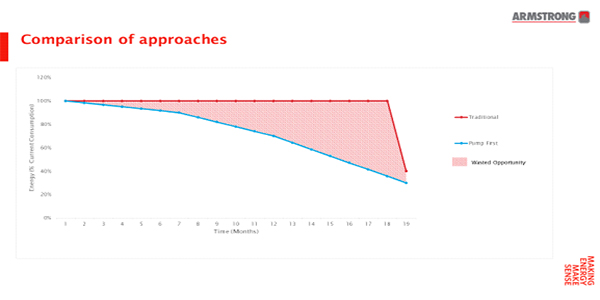

It frequently takes as long as a year and a half to reach the implementation stage of a capital expenditure energy saving project. Typically, the first 6 months are spent collecting data, months 6 to 9 involve a data analysis phase, then technology solutions and a business plan are developed in months 9 to 12. Over the next 6 months stakeholders make their decisions until (18 months after initial discussions) the project is implemented. During that year and a half, not a single kW of energy is saved. With the latest generation of Armstrong Design Envelope (DE) pump technology, however, building owners and occupiers could be saving energy from day 1, month 1 of the initial discussions.

The Armstrong Design Envelope pump first approach - Flow Informs;

The technology that is resident in Armstrong’s DE pumps makes it possible to start saving money from day 1, rather than losing 18 months of potential energy savings. Armstrong DE pumps not only function as a SMART pump, they are more accurate than a traditional flow meter. The Armstrong DE pumps come embedded with Active Performance Management software that is built on Design Envelope technology and is powered by IBM Watson intelligence to learn, predict and optimize in real time.

Following the Armstrong DE pump first approach the pump replacement aspect of the project (a relatively minor part of the overall capital expenditure) is carried out early in the data collection phase. Using the advanced Active Performance Management software within the Design Envelope pumps allows up to 10% of the total system energy to be saved more than a year ahead of full implementation of the upgrade.

The building and load-specific information obtained through the Armstrong DE pumps identifies opportunities for system optimisation with high cost/benefit ratios and assists product selection and system design for the upgrade project, whilst actual, measurable energy savings are demonstrated throughout this process to provide a more persuasive business case for stakeholders. Breaking the project down into smaller sub-projects improves cash flow, and the business case begins to write itself. Depending on the system and load profiles total energy savings of up to 40% are possible.

|

If you are working with building owners who might benefit from the Armstrong DE Pumps First approach, just give us a call and we will happily work with you to find a better solution.

Read the full article at the link below.