Trimming the waste

Today’s HVAC system components are highlyefficient, but the key to overall system efficiency lies in designing specifically to exploit the part-load conditions under which the equipment will operate throughout its lifetime.

|

|

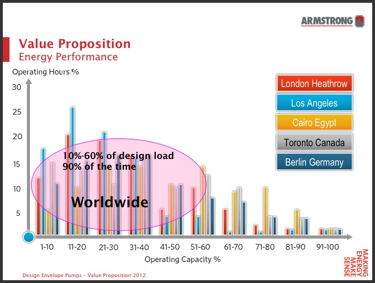

Figure 1: Research shows that systems operate between 10% and 60% of design load for 90% of the time |

Across the world, irrespective of whether the equipment is employed for heating or cooling, research shows that systems operate at between 10% and 60% of design load for 90% of the time. See Figure 1.

Even though our industry has embraced variable speed technology (purpose-designed for part-load), there are still instances in which traditional approaches to system design (developed for a fixed-speed world) slip in to projects. This results in higher up-front costs and disappointing energy savings, as the design decisions fail to exploit the capabilities of the technology to the full (during the 90% of time when the system is operating at between 10% and 60% of design load). So where do these out-of-date design approaches tend to creep in? And how can these potential areas of wastage be avoided?

Some areas to address include:

• Effective choice of a control strategy for the building

• Operation of key components along their natural curve

• Efficient staging of key energy consuming components

• Rethinking duty/standby

Perhaps the most important issue to address is the choice of control strategy. There are numerous projects in which all variable speed components are specified for the system, making it possible to operate extremely efficiently at part load. This can only be fully achieved, however, if the system is designed around a demand-based (rather than a capacity-based) control strategy.

In control

Capacity-based control focuses on the equipment being at its most efficient when operating at 100% design flow. As already discussed, the system will operate at between 10% and 60% of design flow for nearly all of the time. So this form of control clearly fails to harness the full energy and cost saving potential. Demand-based control, however, focuses on operating each component at its most efficient point to meet the actual load.

If a variable frequency drive is added to a HVAC component such as a pump or fan, there is huge potential to improve partload efficiency due to the pump fan laws. If a rotating device is allowed the flexibility to operate along its natural curve, this can increase operating efficiency by 400%. These efficiency improvements can only be achieved, however, if the pump fan law relationship between pressure and rotary speed, along the natural curve, is maintained at decreased speeds.

|

|

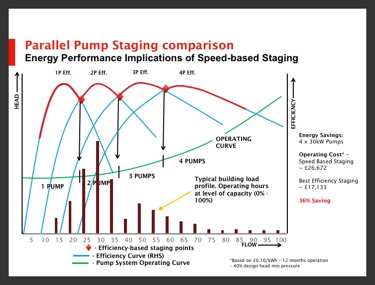

Figure 2: The benefits of efficiency-based staging points |

Wastage can creep in to a HVAC design when traditional control practices prevent the equipment operating at this ‘sweet spot’, for example, where a fixed or minimum differential pressure is maintained across the pump supply and return headers. This means the pump will not have the freedom to operate along its natural vurve and will consequently consume more energy than necessary.

This can be avoided by utilising advanced control methodologies which are integrated into ‘offthe- shelf’ systems, for example Armstrong Fluid Technology’s iFMS, DE 4300 pumps and Tango parallel pumping solutions. So these improvements in equipment performance can be achieved without complex and expensive bespoke programming.

Staging points

Traditional pump staging strategies turn on the next pump when the existing or current pumps reach 95% of maximum speed. Pumps are typically staged-off when the existing or current pumps slow down to 55% of maximum speed. Both of these scenarios involve lost efficiency.

The best practice alternative is to adopt efficiency-based staging points (as opposed to staging points based on pump speed). With this control strategy in place, the system “surfs” across the top of the efficiency curves throughout the day, eliminating the wastage inherent in pump speed-based control approaches (see Figure 2). This improved strategy can achieve energy savings of over 30%.

It is easy to overlook the potential for variable speed systems to reduce the need for full duty standby. In full duty/ standby installations, one pump (sized for full duty) is operational while another of the same size is out of action, simply there to accommodate 100% redundancy in the event of routine maintenance or pump failure. Whilst this might be necessary to provide peace of mind in sites such as hospitals and data centres, there are many other installations (such as hotels, offices, shops, schools or apartment blocks) where it is simply not necessary to have pumps standing idle ‘just in case’.

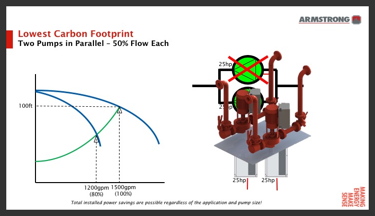

A proven alternative is to specify two smaller pumps to work in parallel (each sized for 50% of the design flow) instead of two pumps each sized for 100% of the duty. This can reduce first installed and lifecycle costs, free up space in the plant room or energy centre, and potentially halve the embodied carbon for the installation.

|

|

Figure 3: With a variable speed pump, maximum designed flow from one pump is around 80% rather than 50% |

Designers often overlook this opportunity because it is assumed that, if a pump should fail, or require routine maintenance, the remaining pump (sized for 50% of the duty) will not be sufficient to maintain adequate comfort conditions for the building. This is not the case, however.

As Figure 3 demonstrates, with a latest generation variable speed pump, maximum design flow from one pump is around 80% rather than 50%.

Actual demand

Our detailed analysis of actual demand in commercial buildings (based on data from one of our installations at Canary Wharf) identified that demand only went above 80% of load on six days in a year. So, for the overwhelming majority of operating requirements, a maximum design flow of 80%, rather than 100%, is sufficient if one of the pumps should fail or require maintenance. Even on the few days a year when demand exceeds 80% flow, we can identify, from cooling and heating coil characteristics, that approximately 95% or greater output from the emitters would still be delivered, in real terms, from a single pump.

Depending on the application, it may therefore be feasible to halve the embodied carbon for this aspect of the project.

To conclude, variable speed technology has revolutionised our industry, and there are now significant opportunities to deliver impressive improvements in environmental performance for the buildings we supply. If we are to fully exploit the opportunities presented by these technologies in the future, however, we need to avoid the traditional approaches to design that might otherwise lock us in the past.

Steve Rees is sales director, Armstrong Fluid Technology